SPECIALIZED PHARMACEUTICAL EMULSIONS

SPECIALIZED

PHARMACEUTICAL EMULSIONS

1.INTRODUCTION:

1.1 DEFINITION

“A biphasic system consisting of two immiscible liquids, one

of which (the dispersed phase) is finely and uniformly dispersed as globules

throughout the second phase (the continuous phase).” Since emulsions are a

thermodynamically unstable system, a third agent, the emulsifier is added to

stabilize the system (Agarwal and Rajesh, 2007).

Emulsifier stabilizes the system by forming a thin film

around the globules of dispersed phase (Javed et al., 2008).

Either the dispersed phase or the continuous phase may vary

in consistency from that of a mobile liquid to semisolid (Alfred, 2005).

Thus, pharmaceutical emulsions range from lotions (low viscosity)

to creams (high viscosity). The particle size of the dispersed phase commonly

ranges from 0.1 to 100 μm (Agarwal and Rajesh, 2007).

1.2 COMPOSITION

An emulsion

usually consists of following three components:

Aqueous

phase.

Oily phase.

Emulsifying agents.

AQUEOUS PHASE

The aqueous phase of an emulsion consists of purified or

deionized water which contains water soluble drug, preservatives, coloring and

flavoring agents.

OILY PHASE

The oily phase of an emulsion consists of fixed, volatile or

mineral oil which contains oil soluble vitamins and antiseptics. The oil used

in formulation of emulsion should be prevented from autooxidation. For example:

fixed oils are castor oil, cod liver oil, almond oil, liquid paraffin, shark

liver oil, and volatile oil containing turpentine oil, sandal wood oil,

cinnamon oil etc.

EMULSIFYING AGENTS

It is the component of emulsion which binds the two

immiscible liquids, and stabilize the emulsion.

1.3 PARTICLE SIZE

The particle diameter of the dispersed phase generally

extends from: 0.1-100μm.

Micro emulsions globules diameter: 0.1-0.2μm.

1.4 PURPOSE OF EMULSION:

Increased drug solubility; many drugs have limited aqueous

solubility but have maximum solubility in oil phase of emulsion. 3

Increased drug

stability; many drugs are more stable when incorporated into an emulsion rather

than in aqueous solution.

Prolonged drug action; incorporation of a drug into an

emulsion drugs with can prolong bioavailability, as with certain intramuscular injections

preparation

Improved taste; drugs with unpleasant taste are more

palatable and thus more conveniently administered in emulsion form.

Improved appearance; oily materials intended for topical

applications are more appealing in emulsion form.

1.5 TYPES OF EMULSION

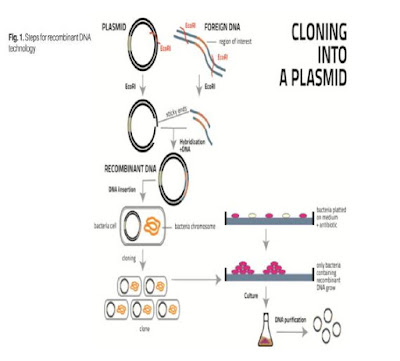

1. OIL IN WATER EMULSION

Pharmaceutical emulsions usually consist of mixtures of

aqueous phase with various oils and waxes. If the oil droplets are dispersed

throughout the aqueous phase, the emulsion is termed oil-in-water (O/W) as shown

in Figure 1.

Characteristics

Fats or oils for oral administration, either as medicaments

in their own right, or as vehicles for oil soluble drugs, are always formulated

as oil in water (O/W) emulsions (Aulton, 1996).

They are non-greasy and are easily removable from the skin

surface

They are used externally to provide cooling effect and

internally to also mask the bitter taste of oil.

Water soluble drugs are more quickly released from O/W

emulsion.

O/W emulsion give a positive conductivity test as water, the

external phase is a good conductor of electricity (Javed et al., 2008).

Examples

Vanishing cream

mayonnaise

vinaigrette

2. WATER

IN OIL EMULSION

A system in which the water is dispersed as globules in the

oil continuous phase is termed waterin-oil emulsion (W/O) as shown in Figure 2.

Figure 2. W/O emulsion.

Characteristics

Water-in-oil emulsions will have an occlusive effect by

hydrating the stratum corneum and inhibiting the evaporation of eccrine

secretions.

W/O emulsion is also useful for cleansing the skin of oil

soluble dirt, although its greasy texture is not always cosmetically acceptable

(Aulton, 1996).

They are greasy and not water washable and are used

externally to prevent evaporation of the moisture from the surface of skin e.g.

cold cream.

Oil soluble drugs are more quickly released from W/O

emulsion. They are preferred for formulation meant for external use like cream.

W/O emulsion is not given a positive conductivity tests,

because oil is the external phase which is a poor conductor of electricity

(Javed et al., 2008).

Examples

Butter

Propofol

Nivea cream

3. MULTIPLE EMULSIONS

A double emulsion (or multiple emulsion) is an emulsion of an

emulsion. That is, it is an emulsion structure with coexisting water-in-oil

(W/O) and oil-in-water (O/W) morphologies.

There are two main types of double emulsion:

water-in-oil-in-water (W/O/W)

oil-in-water in-oil (O/W/O).

The oil droplets of a W/O/W emulsion have water droplets

dispersed within them, and the water droplets of an O/W/O emulsion contain

dispersed oil droplets.

Hence, double emulsion

has three distinct bulk phases and two oil–water interfaces, as compared with

the two bulk phases and single oil–water interface of an ordinary emulsion. The

presence of these two kinds of interfaces means that two different emulsifying

agents are typically required in order to formulate a double emulsion, one to

stabilize the inner droplets (the primary emulsion) and another to stabilize

the outer droplets (the secondary emulsion)

( Eric Dickinson et al ,2010)

Examples;

vancomycin prednisolone

Classification:

With optical microscopy method, multiple emulsions are

classified as

Coarse (> 3 micrometer in diameter)

Fine (1-3 micrometer in diameter)

Micro-multiple emulsions (<1 micrometer in diameter)

4. MICRO EMULSION

Micro emulsions are systems consisting of water, oil and

surfactant, which constitute a single optically isotropic and thermodynamically

stable liquid solution.

There are two types of micro emulsion, one is O/W and the

second is W/O micro emulsion. (Tadros, 1992)

Emulsification

process

Milk is a natural emulsion, which consists of fatty globules

surrounded by a layer of casein, suspended in water. When a pharmaceutical

emulsion is to be prepared the principal consideration is the same as that of

milk.

(Christopher and Dawn, 2008).

1.6 GENERAL METHOD

Generally, an O/W emulsion is prepared by dividing the oily

phase completely into minute globules surrounding each globule with an envelope

of emulsifying agent and finally suspends the globules in the aqueous phase.

Conversely, the W/O emulsion is prepared by dividing aqueous phase completely

into minute globules surrounding each globule with an envelope of emulsifying

agent and finally suspending the globules in the oily phase (Christopher and

Dawn, 2008).

1. CONTINENTAL OR DRY GUM METHOD

Extemporaneously emulsions are usually made by continental or

dry gum method. In this method, the emulsion is prepared by mixing the

emulsifying agent (usually acacia) with the oil which is then mixed with the

aqueous phase.(Christopher and Dawn,2008).

2. WET GUM METHOD

In this method, the proportion of the constituents is same as

those used in the dry gum method; the only difference is the method of

preparation. Here, the mucilage of the emulsifying agent (usually acacia) is

formed. The oil is then added to the mucilage drop by drop with continuous

Trituration (Christopher and Dawn, 2008).

3. BOTTLE METHOD

This method may be used to prepare emulsions of volatile

oils, or oleaginous substances of very low viscosities. It is not suitable for

very viscous oils since they cannot be sufficiently agitated in a bottle. This

method is a variation of the dry gum method.

One part powdered acacia (or other gum) is placed in a dry

bottle and four parts oil are added. The bottle is capped and thoroughly

shaken. To this, the required volume of water is added all at once, and the

mixture is shaken thoroughly until the primary emulsion forms.

4. IN SITU SOAP METHOD

In this method no emulsifying agent is used, but one is

formed "in situ" following a chemical interaction between the

components.

It is also effective in preparing an olive oil and lime water

emulsion, which is selfemulsifying. Equal parts of lime water and olive oil are

added to the bottle and shaken. In the case of olive oil the free fatty acid is

oleic acid that interacts with lime water to form calcium oleate that is

emulsifying agent in this instance. 7

5. MEMBRANE

EMULSIFICATION METHOD

It is a method, which is based on a novel concept of

generating droplets “drop by drop” to produce emulsion. Here, a pressure is

applied direct to the dispersed phase which seeps through a porous membrane

into the continuous phase and in this way the droplets formed are then detached

from the membrane surface due to the relative shear motion between the

continuous phase and membrane surface (Nita et al., 2009).

1.7 TESTS FOR IDENTIFICATION OF EMULSION TYPE;

Several tests are used for identifying the emulsion type.

Although, such tests may be applied rapidly, the results must be interpreted

with caution. It may be possible that such tests can not indicate whether a

multiple emulsion has been produced? Such controversies may be resolved by

microscopic examination (Rawlins, 2005).

1. DILUTION / MISCIBILITY TEST;

Miscibility test involves the addition of continuous phase

e.g. in case of O/W emulsion; the emulsion remains stable upon unlimited

addition of water but will become unstable upon unlimited addition of oil, that

is, the oil will separate. Vice versa is the case with W/O emulsion (Carter,

2007)

2. ELECTRICAL CONDUCTIVITY TEST;

Water is a good

conductor of electricity; hence, an emulsion with water continuous phase will

readily conduct electricity while that with oil continuous phase will not

(Aulton, 1988).

3. STAINING TEST / DYE SOLUBILITY TEST;

In this test, a small amount of water soluble dye, such as

methylene blue is added to the emulsion, now if water is the continuous phase

(O/W emulsion), dye will dissolve uniformly throughout the system. If oil is

the continuous phase (W/O emulsion), dye will remain as cluster on the surface

of the system

(Alfred et al.,)

4. COBALT CHLORIDE TEST:

When a filter paper soaked in cobalt chloride solution is

added to an emulsion and dried, it turns from blue to pink, indicating that the

emulsion is o/w type.

5. FLUORESCENCE TEST:

If an emulsion on exposure to ultra-violet radiations shows

continuous florescence under microscope, then it is Water in Oil (w/o) type and

if it shows only spotty fluorescence, then it is Oil in Water (o/w) type

emulsion.

1.8 THEORIES OF EMULSIFICATION

Many theories have been advanced in an attempt to explain how

emulsifying agents promote emulsification and maintain the stability of the

emulsion. Although certain of these theories apply rather specifically to

certain types of emulsifying agents and to certain conditions, they may be

viewed in a general way to describe the manner in which emulsion may be

produced and stabilized. Among the most prevalent theories are

1. SURFACE TENSION THEORY

2. THE ORIENTED-WEDGE THEORY

3.THE PLASTIC OR INTERFICIAL FILM THEORY.

All liquids have tendency to assume a shape having the

minimal surface area exposed. For a drop of liquid , that shape is the sphere.

It possess internal forces that tend to promote association of the molecules to

resist distortion of the sphere. If two or more drops of the same liquid come

into contact with one another, the tendency is for them to join or to coalesce,

making one larger drop having a smaller surface area than the total surface

area of the individual drops. This tendency of

1.SURFACE TENSION THEORY:

The use of surfactants as emulsifiers and stabilizers lowers

the interfacial tension of the two immiscible liquids, reducing the repellent

force between the liquids and diminishing each liquid attraction for its own

molecules. Thus , the surfactants facilitate the breaking up of large globules

into smaller ones, which then have a lesser tendency to reunite or coalesce.

2.ORIENTED –WEDGE THEORY:

This assumes mono molecular layers of emulsifying agent

curved around a droplet of the internal phase of the emulsion. This based on

the presumption that certain emulsifying agents orient themselves about and

within a liquid in a manner reflective of their solubility in that particular

liquid. In a system containing two immiscible liquids, presumably the

emulsifying agent is preferentially soluble in one of the phases and is

embedded more deeply and tenaciously in that phase than the other. Because many

molecules of substances upon which theory is based(soaps) have a hydrophilic

head and hydrophobic tail, the molecule position or orient themselves into each

phase. Depending on the shape and size of the molecules, their solubility

characteristics, and thus their orientation, the wedge shape envisioned for the

molecules causes either oil globules or water globules to be surrounded.

Generally , an emulsifying agent having a greater hydrophilic than hydrophobic

character will promote an O/W emulsion and a W/O emulsion results from use of

an emulsifying agent that is more hydrophobic than hydrophilic. Putting it

another way, the phase in which emulsifying agent is more soluble will become

the continuous phase. Although this theory may not represent a totally accurate

depiction of the molecular arrangement of the emulsifier molecules, the concept

that water soluble emulsifiers generally do form o/w emulsion is important and

is frequently encountered in practice.

3.PLASTIC OR INTERFACIAL FILM THEORY:

It places the emulsifying agent at the interface between the

oil and water, surrounding the droplets of the internal phase as a thin layer

of film adsorbed on the surface of the drops. The film prevents contact and

coalescing of the dispersed phase ; the tougher and more pliable the film, the

greater the stability of the emulsion. Naturally enough of the film forming

material must be available to coat the entire surface of each drop of the

internal phase. Here again , the formation of an o/w emulsion depends on the

degree of solubility of the agent in the two phases, with water soluble agents

encouraging o/w emulsion and oil soluble emulsifiers the reverse.

In actuality, it is unlikely that a single theory of

emulsification can explain the means by which the many and varied emulsifiers

promote emulsion formation and stability. It is more than likely that even

within a given emulsion system, more than one of the aforementioned theories

play a part. For instance, lowering of the interfacial tension is important in

the initial formation of an emulsion, but the formation of a protective wedge

of molecules or film of emulsifier is important for continued stability. No

doubt certain emulsifiers are capable of both tasks.

2. EMULSIFYING AGENTS:

2.1 DEFINITION

“the chemical agents that are used to reduce the coalescence

between the 2 immiscible liquids are called emulsifying agents”

2.2 PROPERTIES

OF EMULSIFYING AGENT:

It must be compatible with formulation ingredients.

Must not interfere with stability and efficacy of the

product.

should be non toxic.

should be stable and not deteriorate in the prepration.

Should be odourless, colourless and tasteless

Should increase the viscosity of the product.

2.3 MECHANISM OF EMULSIFYING AGENTS:

When 2 immiscible liquids are mixed they form separate layers

and the surface free energy of the system is increased due to interfacial

tension, different densties of 2 phases and large surface area of dispersed

phase. To stabilize it emulsifying agent is added, the emulsifying agent first

adsorb at the surface of interface and when interface becomes saturated and no

further space remaining then emulsifying agent moves toward the bulk of the

solution. The emulsifying agent make the two phases miscible in a manner that

the lipophilic portion of it is towards oily phase and hydrophilic towards the

aqueous phase. Miscelles are formed at CMC consisting of 50-150 molecules of

emulsifying agent and emulsification occurs. So according to theories

emulsifying agent stabilizes the emulsion by

Reducing surface tension

Reducing interfacial tension

form film around the droplet

Provides electric potential

2.4 CLASSIFICATION OF EMULSIFYING AGENTS:

There are many types of emulgent available but for

convenience they can be devided into two main classifications:-

Synthetic or semi synthetic surface active agent

Naturally occurring materials and their derivatives

These devisions are quite arbitrary and some materials may

justifiably be placed in more than one category.

2.4.1 SYNTHETIC AND SEMISYNTHETIC SURFACE ACTIVE AGENTS:

There are 4 main categories of these materials:

a) Anionic

b) Cationic

c) Non ionic

d) Amphoteric

(lecithin)

a) Anionic surfactants:

In aqueous solution these compounds dissociate to form

negatively charged anions that are responsible for there emulsifying ability.

They are widely used because of their cheapness but because of their toxicity

are only used for externally applied preparations.

1: Alkali metals and ammonium soap:

Emulgents in this group consist mainly of the sodium< potassium

or ammonium salts of long chain fatty acids such as sodium stearate.

They produce stable emulsion but because in acidic conditions

these materials will precipitate out as free fatty acids these materials are

most efficient in alkaline medium. this type of emulgent can also be formed by

reacting an alkali such as potassium , sodium or ammonium hydroxide with a

fatty acid. The latter may be a constituent of a vegetable oil, oleic acid and

ammonia for example

are reacted together to

form a soap responsible for stabilizing white liniment these emulgents are

incompatible with polyvalent cations often causing phase reversal and it is

therefore necessary that deionized water is used in their preparation.

2:Soap of divalent and trivalent metals:

Only the calcium salts are commonly used and often formed in

situ during prepration of the product by interacting the appropriate ftty acid

with calcium hydroxide. For example oleic acid is reacted with calcium

hydroxide to produce calcium oleatewhich is emulsifieng agent for both zinc

cream BP and some formulations of oily calamine lotion.

These emulgents will only produce W/O emulsions.

3:Amine soaps:

A number of amines form salts with fatty acids. One of most

important of these is based on triethanolamine and widely used in both

pharmaceutical and cosmetic products. For example triethanolamine form stable

O/W emulsion and is formed by reaction between triethanolamine and appropriate

fatty acid.

4:Sulfated and sulfonated compounds:

An example is sodium lorayl sulfate which is widely used to

produce O/w emulsions. It is used with cetostearyl alcohol to produce

emulsifying wax which stabilize such preprations as aquous cream.

Sulfonated compounds are much less widely used as emulgent .

materials of this class include sodium dioctylsulfosuccinate and are more often

used as wetting agent or for their detergency.

b) Cationic surfactants:

In aqueous solutions these materials dissociate to form

positively charged cations that provide the emulsifying properties. The most

important group of cationic emulgents consist of the quaternary ammonium

compounds. Although these compounds are used for their disinfectant and

preservative properties they are also useful O/W emulsifiers.

Because of toxicity of cationic surfactants they tend to be

used only for the preparation of antiseptic creams where the cationic nature of

the emulgent is also responsible for the products antiseptic properties.

Cetrimide is one of the most useful of these emulgent and

used at a concentration of 0.5% with 5% cetostearyl alcohol for the formulation

of cetrimide cream.

c) Non-ionic surfactants:

These products range from oil soluble compounds stabilizing

w/o emulsions to water soluble materials giving o/w products. They have low

toxicity and irritancy therefor be used for orally and parenterally

administered preparations. They also have greater degree of compatibility then

cationic and anionic emulgents.

Most non-ionic surfactants are based on:

A fatty acid, the hydrocarbon chain of which provides the

hydrophobic moiety

An alcohol, which provides the hydrophilic part of the

molecule

By varying the relative proportions of the hydrophilic and

hydrophobic grouping many different products can be obtained.

1.glycol and glycerol esters:

glyceryl monostearate is a strongly hydrophobic material that

produce weak w/o emulsions. The addition of small amount of sodium, potassium

or triethanolamine salts of suitable fatty acids will produce a

self-emulsifying glyceryl monostearate which is a useful o/w emulsifier.

Self-emulsifying monostearin is glyceryl monostearate to which anionc soaps

have been added. This

combination is used to

stabilize hydrocortisone lotion. Other examples include glyceryl monooleate,

diethylene glycol monostearate and propylene glycole monooleate.

2:Sorbitan esters:

These are produced by the esterification of one or more of

the hydroxyl groups of the sorbitan with either oleic, palmitic or stearic

acid.

This range of surfactants exibit lipophilic properties and

tend to form w/o emulsions.

3. Polysorbates:

Polyethylene derivatives of the sorbitan esters give us

polysorbates.

Polysorbates are generally used in conjunction with the

corresponding sorbitan ester to form a complex condensed film at the o/w

interface.

Other non ionic oil soluble materials such as glyceryl

monostearate ,cetyl or stearyl alcohol or propylene glycole monostearate can be

incorporated with polysorbates to produce self emulsifying preprations e.g

polawex containas cetyl alcohol with a polyoxyethylene sorbitan ester.

4.Fatty alcohol polyglycol esters:

These are condensation products of polyethylene glycol and

fatty alcohols.

Perhaps the most widely used is macrogol cetostearyl ether or

cetomacrogol which is polyethylene glycole monocetyl ether. This is very useful

water soluble o/w emulgent because of high water solubility it is necessary to

introduce an oil soluble auxiliary emulsifier when formulating emulsions’

5.Fatty acid polyglycol esters;

The stearate esters of polyoxyl stearates are the most widely

used of this type of emulgent. Polyoxyethylene 40 stearate is a water soluble

material often used with stearyl alcohol to give oil in water emulsion.

6.Poloxakols:

Poloxacols are polyoxyethylene/polyoxypropylene copolymers

and a comprise a very large group of compounds. Some of which are used as

emulsifying agent for intravenous emulsions.

7.Heigher fatty alcohols:

The hexadecyl and octadecyl members of this series of

saturated aliphatic monohydric alcohols are useful auxillary emulsifying

agents. Part of their effect come from their ability of increasing viscosity

thereby reducing creaming. Cetostearyl alcohol also form interfacial film with

hydrophilic surface active agents, such as sodium lauryl sulfate, cetrimide or

cetromacrogol 1000 and so stabilize o/w emulsions.

2.4.2 NATURALLY OCCURRING MATERIALS AND THEIR DERIVATIVES:

They have 2 main disadvantages:

They show considerable batch to batch variation in

composition and hence in emulsifying properties

Many are susceptible to bacterial mould growth.

For these reasons they are not widely used in prepration of

products requiring longer half life.

Natural polysaccharides:

The most important emulsifying agent in this group is acacia.

This stabilizes o/w emulsion by forming strong multimolecular film around each

oil globule and so coalescence is retarded by the presence of a hydrophilic

barrier between the oil and water phases.

Because of its low viscosity creaming will occur readily and

therefore a suspending agent such as tragacanth or sodium alginate can also be

included.

Semi-synthetic polysaccharides:

In order to reduce the

problems associated with batch to batch variation semisynthetic derivatives are

available in o/w emulgents or stabilizers.

Several grades of methylcellulose and carmellose sodium are

available and exert their action in a similar way to that of acacia.

Methylcellulose 20 for example is used at a concentration of 2% to stabilize

liquid paraffin oral emulsion.

3.EQUIPMENTS FOR EMULSION PREPRATION:

3.1 EQUIPMENTS FOR SMALL SCALE PREPARATION:

different techniques are used to prepare emulsion on small

scale some of which are described below:

3.1.1 MORTAR AND PESTLE:

The mortar and pestle can be used for small scale prepration

of emulsion in labs and pharmacy and it is one of the simplest method to be

used.

Advantages:

low cast

simplest operation

Disadvantage:

Final particle size is larger than other equipments

3.1.2 AGITATOR:

Ordinary agitation or shaking may be used the emulsion. This

method is frequently applied by the pharmacist particularly in the

emulsification of easily dispersed low viscosity oils. Under certain conditions

intermittent shaking is considerably more effective then ordinary continuous

shaking. Continuous shaking break not only the phase to be dispersed but also

the dispersion medium thus impair emulsification.

3.1.3 MECHANICAL MIXERS:

Emulsions may be prepared by using one of the several mixers

which are available. Propeller and impeller type mixers that have a propeller

attached to a shaft driven by an electric motor are convenient and portable and

can be used for stirring and emulsification. A turbine mixer has a number of

blades that may be straight or curved with or without a pitch , mounted on

ashaft. The turbine tends to give more shear than propeller and is used for

prepration of high viscosity emulsions.

Small electric mixers may be used to prepare emulsion at the

prescription counters. They save time and energy and produce satisfactory

emulsions, when emulsifying agent is acacia or agar.

3.2 EQUIPMENTS FOR LARGE SCALE PREPRATION:

Several equipments are used :

3.2.1 COLLOID MILLS:

High shear colloid mills or rotor/stator mixers are widely

used for emulsion prepration. The principle of operation of the colloid mill is

the passage of the mixed phases of the emulsion formula between a stator and a

high speed rotor revolving at speed of 2000 to 18000 rpm.the emulsion mixture

while passing between the rotor and stator is subjected to tremendous shearing

action which effects a fine dispersion of uniform size. The shearing action

usually rise the temperature of emulsion so a coolant is used to absorb the

excess heat.

Advantage:

Very high shearing force can be generated

Very fine particles can be prepared

Useful for prepration of relatively viscous emulsions

3.2.2 HOMOGENIZER:

Impeller type of equipment frequently produces a satisfactory

emulsion however for further reduction in particle size homogenizer may be

employed. Homogenizer may be used in one of the 2 ways:

The ingredients in the emulsion are mixed and then passed

through the homogenizer to produce the final product

A coarse emulsion is prepared in some other way and then

passed through a homogenizer for the purpose of decreasing the particle size

and obtaining a greater degree of uniformity and stability.

It is postulated that circulation and turbulence are responsible

mainly for the homogenization that take place.

3.2.3) ULTRASONIC DEVICES:

The preparation of emulsion by the use of ultrasonic

vibrations is also possible. An oscillator of high frequency 100-500 kHz is

connected to two electrodes between which is placed a piezoelectric quartz

plate. The quarts plate and electrodes are immersed in an oil bath and when the

oscillator is operating , high frequency waves flow through the fluid.

Emulsification is accomplished by simply immersing a tube containing the emulsion

ingredients into this oil bath.

3.2.4) MICROFLUIDIZER:

Microfluidizers have been used to produced very fine

particles. The process subjects the emulsion to an extremely high velocity

through microchannels into an interaction chamber as a result particles are

subjected to shear, turbulence, impact and cavitation. Two advantages of this

type of equipment are lack of contamination in the final product and ease of

production scale up.

4. DETERMINATION OF HLB :

William Griffin, in the late 1940s, introduced the

Hydrophilic-Lipophilic Balance system (HLB)as a way of figuring out which

emulsifier would work best with the oil phase of an emulsified product. All

emulsifiers have a hydrophilic head (water loving) that is generally composed

of a water soluble functional group and a lipophilic tail (oil loving)

generally composed of a fatty acid or fatty alcohol.The proportion between the

weight percentages of these two groups in a surfactant molecule is an

indication of the behaviour that may be expected from that product. An

emulsifier that is lipophilic in character is assigned a low HLB number and an

emulsifier that is hydrophilic in character is assigned a high number. The

midpoint is approximately ten and the assigned values have ranged from one to

forty.

4.1) THEORY

The theory behind HLB is that emulsifier having low HLB value

tend to be oil soluble and materials having high values tend to be water

soluble. However, this doesn’t always be

right, e.g., two emulsifiers may have the same HLB and

exhibit different solubility characteristics. Further, one should take a point

into consideration that chemical type

alone doesn’t establish hydrophilic-lipophilic balance. Thus,

soaps may range from strongly hydrophilic for sodium laurate to strongly

lipophilic for aluminium oleate. 15

4.2)

DETERMINATION OF HLB BY CALCULATION

Calculation of HLB value of surfactant is very important in

product quality and yield points of view. HLB values can be calculated

theoretically or may be determined by experimentally. The experimental method

is very long and laborious and was described long back ago by William

Griffin in 1949. Formulas for calculating HLB values may be

based on either analytical or composition data. For most polyhydric alcohol

fatty acid esters approximate values may

be calculated with the formula:

These formulas are

satisfactory for non-ionic surfactants of many types. However, non-ionic

surfactants containing propylene oxide, butylene oxide exhibit behaviour which

has

not been related to composition. In addition, the HLB values

of ionic surfactants do not follow a weight percentage basis because even

though the hydrophilic portion is low molecular

weight the fact that its ionization lends extra emphasis to

that portion and therefore makes the product more hydrophilic. For these

products, the experimental method must be used.

4.3) DETERMINATION OF HLB “REQUIREMENT”

HLB “requirement” is the amount of surfactant required to

make an oil to remain in solution. Variation of the proportion of the blended

emulsifiers has been preferred to obtain best

results. When two emulsifiers of known HLB are thus blended

for use with a given oil there is an optimum ratio that best emulsification and

the HLB at this ratio is said to be the required HLB for the oil (to give that

type of emulsion, whether O/W, W/O solubilisation, etc.). This is

expressed by the equation.

HLB(OIL)=WA*HLB( A )+WB *HLB (B) / WA+WB

Where, WA= the amount (weight) of the 1st emulsifier (A)used.

WB= the amount (weight) of the 2nd emulsifier (B) used

at the optimum ratio giving the best emulsion.

HLBA, HLBB= the assigned HLB values for

emulsifiers A and B.

HLBoil= the “required HLB” of the oil for the type of

emulsion being studied.

4.4) APPLICATIONS OF SURFACTANTS DEPENDING ON HLB

The HLB system is very useful to distinguish the surfactants

according to their applications. Generally, the applications

for nonionic surfactants within the following HLB ranges are

as follows

5. CREAMING AND

SEDIMENTATION:

5.1) CREAMING:

Creaming is the upward movement of the droplets relative to

the continuous phase. It occurs when dispersed phase is less dense than the

continuous phase as in O/W type emulsion.

5.2) SEDIMENTATION:

Sedimentation is defined as downward movement of droplets

relative to the continuous phase. If internal phase is heavier than the

external phase, globules will tend to settle down causing sedimentation as in

the case of W/O type emulsion.

Creaming is reversible. Upon shaking creamed portion of the

emulsion can be redistributed homogenously but still creaming and sedimentation

are often undesirable due to following reasons: If insufficient shaking is

employed before each dose improper dosage of the internal phase may result. Not

acceptable by the consumer

How to overcome :

By using stokes equation,

So there are 3 factors that govern rate of settling of

droplets: I. Diameter of suspended droplets II. Viscosity of suspending

medium III. Difference of densities between dispersed phase and the dispersion

medium. But we can use only first two factors to reduce rate of creaming or

sedimentation. 1. Reduction of particle size as rate of movement is a square

root function of the particle diameter. Particle diameter can be reduced up to

0.1μm. 2. Most frequent approach is to raise viscosity of the continuous phase

for this we can use viscosity improver or thickening agent for example

Methylcellulose, tragacanth

or Sodium alginate. But

we can only increase thickness up to the acceptable limit so that emulsion can

be poured easily. 3. Theoretically if internal and external phase densities are

same there would be no creaming or sedimentation but it’s not possible

practically as temperature change density.

5.3) COALESCENCE AND BREAKING: COALESCENCE: Complete

fusion of droplets to decrease number of droplets that can lead to breaking of

emulsion. Aggregation precedes coalescence in emulsion; however coalescence

does not necessarily follow from aggregation. Coalescence is irreversible as in

coalescence protective sheath of emulsifier around dispersed droplets no longer

exist. BREAKING: Separation of internal phase and separation of that

phase into a layer is called breaking and emulsion is called cracked or broken.

How to overcome coalescence? Coalescence

can be overcome by using combination of surfactants that provide certain

advantages: Ø-water

interface Ø of

elastic film that will not rupture upon collision of emulsion droplets

Additional beneficial effect of mixed emulsifier films could result from an

increase in viscosity of the interfacial emulsifier film. A viscous interfacial

film could enhance emulsion stability because thinning of the film at the point

of droplet to droplet contact would be inhibited. 5.4)

INVERSION: An

emulsion is said to be inverted when it changes from O/W type to W/O type or

vice versa. Following factors can cause inversion of emulsion:

Ø-for

example an O/W emulsion having sodium stearate as the emulsifier can be

inverted by the addition of calcium chloride, because the calcium stearate

formed is a lipophilic emulsifier and favors the formation of a W/O product. Ø two phases is being cooled. This takes place presumably because

of the temperature dependent changes in the solubilities of the emulsifying

agents. How to avoid inversion? Ø exceed

50% of the total volume of the emulsion. Ø 20

6. EVALUATION OF

EMULSION STABILITY:

To speed up stability evaluation of emulsion formulator

commonly places the emulsion under some sort of stress. Stress conditions

normally employed for evaluating the stability of emulsions include: 1. Aging

and temperature 2. Centrifugation 3. Agitation

6.1)AGING AND TEMPERATURE: Ø

varying period of time at temperatures that are higher than

normally encountered.

Ø is

cycling between 4 and 45°C.This type of cycling approaches realistic shelf

conditions but places emulsion under enough stress to alter various emulsion

parameters. ØTemperature

changes cause varied effects on following parameters of emulsion: ity ØAn ‘’acceptable’’ emulsion should survive two or three freeze

thaw cycles between - 20 and 25°C with no visible signs of instability

similarly a stable emulsion should survive six or eight heating/cooling cycles

between 4 and 45°C with storage at each temperature for not less than 48 hours.

6.2CENTRIFUGATION: Ø predicted

rapidly by observing the separation of dispersed phase due to either creaming

or coalescence when the emulsion is exposed to centrifugation. Ø therefore accelerates separation. Ø-radius centrifuge for a period of 5 hours is equivalent to

the effect of gravity for about one year. Ø-

3,000 rpm at room temperature. 3. Agitation: Ø

coalescence of droplets take place owing to their Brownian

movements. Simple mechanical agitation can contribute to the energy with which

two droplets impinge upon each other and hence may lead to coalescence and

ultimately breaking of emulsion. Excessive shaking or homogenization also

interferes with the formation of emulsion. Øy

agitation for 24 to 48 hours on a reciprocating shaker approximately 60

cycles/minute at room temperature and at 45°C.

7. ADVANCED PHARMACEUTICAL EMULSIONS:

7.1) MICRO EMULSIONS

7.1.1) HISTORICAL BACKGROUND :

The microemulsion concept was introduced as early as 1940’s

by Hoar and Schulman who generated a clear single-phase solution by titrating a

milky emulsion by hexanol. Schulman and co-worker (1959) subsequently coined

the term microemulsion.

7.1.2) DEFINITION :

“ Micro-emulsions is homogenous, transparent,

thermodynamically stable dispersions of water and oil, stabilized by a

surfactant, usually in combination with a co-surfactant.”

7.1.3) ALTERNATIVE

NAMES :

Microemulsions are also called as,

Transparent emulsion, Swollen micelle, Micellar solution

,Solubilized oil

7.1.4) COMPOSITION OF MICRO-EMULSION :

Microemulsions is defined as transparent dispersion

consisting of,

1. Oil

2. Surfactant

3. Co-surfactant

4. Water

7.1.5) ADVANTAGES:

o Increase the rate of absorption

o Increase bio-availability

o Helpful in taste masking

o Eliminates variability in absorption

o Helps in solubilizing lipophilic drugs

7.1.6) DISADVANTAGES:

o Use of large concentration of surfactant and co-surfactant

necessary for the stabilizing micro droplets.

o Limited solubilizing capacity for high melting substances.

o Microemulsion stability is influenced by environmental

parameters such as, temperature & ph. These parameters change upon

microemulsion delivery to the patients.

7.1.7) TYPES OF MICROEMULSIONS :

Microemulsions are of 3 types.They are

1) O/W Microemulsion

2) W/O Microemulsion

3)Bi-continuous microemulsion

o O/W Microemulsion where in droplets are dispersed in the

continuous aqueous phase.

o W/O Microemulsion where in water droplets are dispersed in

the continuous oil phase.

o Bi-continuous microemulsion where in micro domains of oil

& water are inter dispersed within the system.

In all the three types of microemulsions,the interface is

stabilized by an appropriate combination of surfactants and/or co- surfactants.

7.1.8) PREPARATION METHODS OF MICROEMULSIONS :

Following are the different methods used for the preparation

of the microemulsions :

1) Phase titration method

2) Phase inversion method

Phase-titration method :

1. Dilution of an oil-surfactant mixture with water.[W/O] 2.

Dilution of a water surfactant mixture with oil.[O/W] 3. Mixing of all

components at once, in some systems, the order of ingredients addition may

determine whether a microemulsion forms are not.

Phase-inversion method :

Temperature range in which an o/w microemulsions inverts to a

w/o type. Using non-surfactants: polyoxyethylene are very suspectible to

temperature. with increasing the temperature, the polyoxyethylene group becomes

dehydrated, altering critical packing parameter which results in the phase

inversion. For ionic surfactants: increasing temperature, increase the

electrostatic repulsion between the surfactant headgroups thus causing reversal

of film carvature. Hence, the effect of temperature is opposite to the effect

seen with non-ionic surfactants.

7.1.9) FACTORS AFFECTING MICROEMULSION FORMATION :

1. Packing ratio

2. Property of surfactant

3. Property of oilphase

4. Temperature

5. Chain length

6. Nature of co-surfactant

APPLICATIONS :

1) Oral delivery system 2) Parenteral delivery system 3)

Ophthalmic delivery system 4) Microemulsions in detergency 5) Microemulsions in

cosmetics 6) Microemulsions in foods

:

CONCLUSION : Microemulsions are potentially quite powerful

alernative carrier system for delivery because of high solubilization capacity,

transparency, thermodynamic stability, ease of preparation, and high diffusion

and absorption rates through skin, when compared to solvent without the

surfactant system. A number of factors must be considered when using

microemulsions as drug delivery system such as surfactant, co-surfactant, oils,

pH, HLB, temperature etc.

Figure: Microemulsion and Std Emulsion

7.2 MACROEMULSION

Macroemulsions are kinetically stabilized mixtures of at

least two immiscible liquids where one of the liquids has droplets with a

diameter greater than 0.1 μm. Macroemulsions scatter light effectively and

therefore appear milky, because their droplets are greater than a wavelength of

light. As with all

emulsions, one phase serves as the dispersing agent. It is often called the

continuous or outer phase. The remaining phase(s) are disperse or inner

phase(s), because the liquid droplets are finely distributed amongst the larger

continuous phase droplets.This type of emulsion is thermodynamically unstable,

but can be stabilized for a period of time with applications of kinetic energy.

Surfactants (emulsifiers) are used to reduce the interfacial between the two layers,

and induce macroemulsion stability for a useful amount of time.

IUPAC definition

Emulsion in which the particles of the dispersed phase have

diameters from approximately 1 to 100 μm.

Macro-emulsions comprise large droplets and thus are

"unstable" in the sense that the droplets sediment or float,

depending on the densities of the dispersed phase and dispersion medium.

Separation of the dispersed and continuous phasesusually occurs within

time periods from a few seconds to a few hours, depending upon the viscosity of

the fluid medium and the size and density of the droplets.

7.2.1) TYPES OF MACROEMULSION

Macroemulsions can be divided into two main categories based

on if they are a single emulsion or a double or multiple emulsion group. Both categories

will be described using a typical oil (O) and water (W) immiscible fluid

pairing. Single emulsions can be sub divided into two different types. For each

single emulsion a single surfactant stabilizing layer exists as a buffer in

between the two layers. In (O/W) oil droplets are dispersed in water. On the

other hand (W/O) involves water droplets finely dispersed in oil. Double or

multiple emulsion classification is similar to single emulsion classification,

except the immiscible phases are separated by at least two surfactant thin

films. In a (W/O/W) combination, an immiscible oil phase exists between two

separate water phases. In contrast, in an (O/W/O) combination the immiscible

water phase separates two different oil phases

Figure: (A) o/w (B) w/o (C) w/o/w (D) o/w/o

Macroemulsions are, by definition, not thermodynamically

stable. This means that from the moment they are created, they are always

reverting to their original, immiscible and separate state. The reason why

Macroemulsions can exist however, is because they are kinetically stable rather

than thermodynamically stable. This means that while they are continuously

breaking down, it is done at such a slow pace that it is practically stable

from a macroscopic perspective.

7.2.2) STABILITY

Stability of the Macroemulsions are based on numerous

environmental factors including temperature, pH, and the ionic strength of the

solvent.

7.2.3) USES:

Macroemulsions have nearly endless uses in scientific,

industrial, and household applications. They are widely utilized today in

automotive, beauty, cleaning and fabric care products as well as biotechnology

and manufacturing techniques.[5]

Macroemulsions are often chosen over microemulsions for

automotive and industrial applications because they are less expensive, easier

to dispose of, and their tendency to demulsify more quickly is often desirable

for lubricants. Soluble oil lubricants, usually containing fatty oil or mineral

oil in water, are ideal for high speed and low pressure applications. They are

often used for friction reducing needs and metalworking.[6]

Many skin care products, sun screens, and fabric softeners

are made from silicone macroemulsions. Silicone's is chosen because of its

non-irritating and lubricating properties. Different combinations of

macroemulsions and surfactants are the subject of a wide range of biological

research, especially in the area of cell cultures.

|

The following table outlines a few examples of

macroemulsions and their applications:

Macroemulsion

|

Continuous

Phase

|

Dispersed

Phase

|

Application

|

Surfactant

|

|

Diesel

Fuel and Water

|

Diesel

|

Water

|

Reducing

fuel emissions[6]

|

Nonionic

surfactants based on aliphatic hydrocarbon tails (examples: alcohol

ethoxylates, fatty acid ethoxylates, sugar esters of fatty acids)[10]

|

|

Silicone

and Water

|

Water

|

Silicone

|

Fabric

Softener,[5]Cosmetics[11]

|

Nonionic

surfactants (example: silicone copolyol)[11]

|

|

Alcohol

and Water

|

Water

|

Alcohol

|

Purifying

contaminated ground water[9]

|

Food

or pharmaceutical quality agents similar to those used in whipped toppings

and shampoos (examples: Polysorbate-20, Tween or Span)[9]

|

|

Isooctane

and Water

|

Isooctane

|

Water

|

Housing

cell cultures[8]

|

Have

bactericide or bacteriostatic properties (example: Lecithin, a phospholipid

found in many animals naturally)[8]

|

7.3

NANOEMULSIONS

7.3.1) INTRODUCTION

The term

"Nanoemulsion" refers to a thermodynamically unstable dispersion of

two immiscible liquids, such as oil and water, stabilized by an interfacial

film of surfactant molecules.

The dispersed phase

typically comprises small particles or droplets, with a size range of 5 nm-200

nm, and has very low oil/water interfacial tension.

Three TYPES OF

NANOEMULSIONS are most likely to be formed depending on the composition:

1-Oil in water

2-water in oil

3-Bi-continuous Nanoemulsions wherein microdomains of oil and water are interdispersed within

the system.

7.3.2) CLASSIFICATION

OF SURFACTANTS:

Nonionic- Fatty

alcohols, glycerol esters, fatty acid esters.

Anionic-Contain

carboxylate groups. Soaps, Sulfonates, Divalent ions.

Cationic- Amines

and quaternary ammonium compounds. Cetyl trimethyl ammonium bromide.

7.3.3) ADVANTAGES OF

NANOEMULSION OVER OTHER DOSAGE FORMS

Increase the rate

of absorption.

Eliminates

variability in absorption.

Helps solublize

lipophilic drug.

Provides aqueous

dosage form for water insoluble drugs.

Increases

bioavailability.

Various routes like

topical, oral and intravenous can be used to deliver the product.

Rapid and efficient

penetration of the drug moiety Provides protection from hydrolysis and

oxidation as drug in oil phase in O/W Nanoemulsion is not exposed to attack by

water and air.

Liquid dosage form

increases patient compliance.

Less amount of

energy requirement.

The use of

Nanoemulsion as delivery systems can improve the efficacy of a drug, allowing

the total dose to be reduced and thus minimizing side effects.

7.3.4) DISADVANTAGES

OF NANOEMULSION BASED SYSTEMS

Use of a large

concentration of surfactant and cosurfactant necessary for stabilizing the

nanodroplets. Limited solubilizing capacity for high-melting substances.

Expensive

Nanoemulsion

stability is influenced by environmental parameters such as temperature and pH.

These parameters change upon Nanoemulsion delivery to patients.

7.3.5) FACTORS TO BE

CONSIDERED IN PREPARATION

Three important

conditions:

Surfactants must be carefully

chosen so that an ultra low interfcial tension (< 10-3 mN/m) can be attained

at the oil / water interface which is a prime requirement to produce

Nanoemulsions.

Concentration of surfactant

must be high enough to provide the number of surfactant molecules needed to

stabilize the microdroplets to be produced by an ultra low interfacial tension.

The interface must be flexible

or fluid enough to promote the formation of Nanoemulsions.

7.3.6) METHODS OF PREPARATION

High pressure homoginization:

Microfluidization

High pressure

homoginization:

This method used a high very high

presssure homoginizer/piston homoginization to produce very small droplet

size up to 1nm.

Microfluidization:

It is patented mixing technology

which uses the microfluidizer.

The device uses a high pressure

positive displacement pump which forces the product through interaction channel

which contains ‘microchannels’.

The product flows through a

microchannels on to an impingement resulting in a very fine particle/droplet

size.

The aqueous and oily phase are

processed in an in line homoginizer to yield a coarse emulsion. Then it is

further proceed to microfluidizer to obtain a nanoemulsion.

The coarse emulsion is passed

through the interaction channel repeatedly to yield a desired size

nanoemulsion.

7.3.7) APPLICATIONS OF

NANOEMULSIONS

Parenteral delivery ,Oral drug

delivery,Topical drug delivery,Ocular and pulmonary delivery &

Nanoemulsions in biotechnology

Parenteral

delivery:

Nanoemulsion formulations have

distinct advantages over macroemulsion systems when delivered parenterally

because of the fine particle Nanoemulsion is cleared more slowly than the

coarse Nanoemulsion formulations offer the several benefits over conventional

oral formulation for oral administration including increased absorption,

improved clinical potency,and decreased drug toxicity. Therefore, Nanoemulsion

have been reported to be ideal delivery of drugs such as steroids, hormones,

diuretic and antibiotics.

A Nanoemulsion formulation of

cyclosporine, named Neoral® has been introduced to replace Sandimmune®, a crude

oil-in-water emulsion of cyclosporine formulation. Neoral® is formulated with a

finer dispersion, giving it a more rapid and predictable absorption and less

inter and intra patient variability.

Topical

delivery:

Topical administration of drugs

can have advantages over other methods for several reasons, one of which is the

avoidance of hepatic first pass metabolism of the drug and related toxicity

effects.

The use of

lecithin/IPP/waterNanoemulsion for the transdermal transport of indomethacin

and diclofenac has also been reported which has increase the permiability of

the human stratum corneum.

Ocular Delivery:

For the treatment of eye

diseases, drugs are essentially delivered topically. O/W Nanoemulsions have

been investigated for ocular administration, to dissolve poorly soluble drugs,

to increase absorption and to attain prolong release profile.The Nanoemulsions

containing pilocarpine were formulated using lecithin, propylene glycol and PEG

200 as co- surfactant and IPM as the oil phase.

Nanoemulsions in biotechnology:

Many enzymes, including lipases, esterases, dehydrogenases and oxidases often function in the cells in microenvironments that are hydrophobic in nature. In biological systems many enzymes operate at the interface between hydrophobic and hydrophilic domains and these usually interfaces are stabilized by polar lipids and other natural amphiphiles.

Enzymatic catalysis in Nanoemulsions has been used for a variety of reactions, such as synthesis of esters, peptides and sugar acetals transesterification; various hydrolysis reactions and steroid transformation. The most widely used class of enzymes in microemulsion-based reactions is of lipases.

7.3.8) USES:

Nanoemulsions could be and have been applied in various aspects of drug delivery including:

Cosmetics and transdermal delivery of drug,

Cancer therapy,

Vaccine delivery,

Prophylactic in bio-terrorism attack,

Non-toxic disinfectant cleaner,

Cell culture technology,

Formulations for improved oral delivery of poorly soluble drug,

Ocular and otic drug delivery,

Intranasal drug delivery,

Pulmonary delivery of drugs.

7.4 MULTIPLE EMULSIONS:

Novel development in emulsion technology. Complex type of multiple system.

7.4.1) TYPES OF MULTIPLE EMULSION:

Types of multiple emulsions –

1. w/o/w system – • Oil droplet surrounded by aqueous phase.

• In most cases, two aqueous phase are identical therefore a W1/O/W1 emulsion is a two component system. In some cases a W1/O/W2 is a three component system.

2. o/w/o system – • Water phase separates internal and external oil phase.

7.4.2) ADVANTAGES -

1. Protect active drug from degradation.

2. High encapsulation efficiency.

3. Prolonged or controlled drug release can be achieved.

4. Easy to produce and scale up. 5. Economical.

7.4.3) DISADVANTAGES -

1. Low thermodynamic stability.

2. It is bulkier system.

3. Disagreeable taste in some case.

7.4.4.) FORMULATION AND MANUFACTURE OF MULTIPLE EMULSION -

• Either by the re-emulsification of a primary emulsion or they can be produced when an emulsion inverts from one type to another.

1-Two step Emulsification(double Emulsification)

2-Micro channel emulsification process

3-Phase inversion technique (one step technique)

4-Membrane Emulsification technique

1.Micro Channel Emulsification Process

• Two type of channel:

T– junction channel: -

2.Modified Double Emulsion Technique

3. Phase inversion.

4..Membrane Emulsification Techniquez

7.4.5) MICROSCOPIC EXAMINATION

color ,consistancy ,Homogenicity. 2. Macroscopic examination – Average globule size & size distribution coarse multiple emulsion > 3micron fine multiple emulsion 1-3 micron micro multiple emulsion <1 micron

7.4.6) APPLICATIONS

• Controlled and Sustained Drug Delivery

• Drug Targeting

• Vaccine Adjuvant

• Cosmetics preparation

• Taste masking of the drug

• Haemoglobin Multiple emulsion as an oxygen Delivery system.

1.Multiple emulsion in controlled release drug delivary.

curcumin extract nanoencapsulated in chitosan and crosslinked with triployphosphate via multiple emulsion shows 96.28% encapsulation efficacy with controllled release.

2.Multiple emulsion in protein delivary Insulin delivary – EPA ,DHA, INSULIN multiple emulsion result shows DHA facilitate intestinal insulin absorption without inducing serious damage.

3.Others – a) For delivery of blood substitutes. b) For drug stability. c) In microencapsulation. d)Thermo reversible multiple emulsions. e) Food processing.

8.OTHER EMULSIONS

8.1 ORAL EMULSIONS

are oral liquids containing one or more active ingredients. They are stabilized oil-in-water dispersions, either or both phases of which may contain dissolved solids. Solids may also be suspended in oral emulsions. When issued for use, oral emulsions should be supplied in wide-mouthed bottles. Firstly prepared oral emulsion was cyclosporin.

8.2 PARENTERAL EMULSIONS

are special o/w emulsions used to feed patients whose medical condition makes them unable to eat normally. Therefore, parenteral emulsions must comply with several specifications. One is that the maximum droplet size must be below 5μm in order to avoid the risk of a pulmonary embolism.

8.3 RADIOPAQUE FLUOROCARBON (RFC) EMULSIONS

were prepared with small particle size and high concentration of the fluorocarbon. When RFC emulsions were injected intravenously in hamsters, rats, and mice with eight types of malignant tumors, the tumors became radiopaque and remained radiopaque for days to weeks after injection. Light and electron microscopy revealed characteristic fluorocarbon vacuoles primarily in the tumor macrophages. Thus RFC emulsions may be useful in detection of malignant tumors.

8.4 GEL EMULSIONS:

A series of novel and stable water in oil w/o gel-emulsions was created by utilizing a new cholesteryl derivative, a low-molecular mass gelling agent, as a stabilizer. The gel-emulsions could be prepared by simple agitation of the mixtures at room temperature, while heating, cooling, and addition of a co-solvent or other additional component are unnecessary. SEM and optical microscopy studies revealed the foam-like structures of the gel-emulsions. Porous polymer monoliths could be prepared by polymerizing gel-emulsions with organic monomers as a continuous phase.

9. PHARMACEUTICAL APPLICATIONS OF EMULSIONS:

Emulsion is used widely in pharmaceutical and cosmetic industries. Pharmaceutical applications are classified according to the route of administration i.e. topical, oral or parenteral. There are following major applications of emulsions in pharmacy.

Dermatological Creams and Lotions:

Creams and lotions are used topically to the affected area only. Nowadays instead of greasy and semisolids, water washable and non-staining products are being used which are more acceptable to patients.

Patient Acceptance and Compliance:

Water insoluble compounds are orally administered as o/w emulsion with pleasant taste e.g.

vitamin A, E, D and K are absorbed more quickly when emulsified.

Bioavailability:

Some therapeutic agents show bioavailability more when given in the form of emulsions e.g. Heparin and insulin.

Modern Drug Delivery Concept:

Non-absorbable macromolecules are absorbed to small extent when given orally as such insulin and heparin and they may even be digested in stomach. But when these agents are given in emulsified form they are not digested and are fully absorbed.

Intravenous Fat Emulsion:

The intravenous fat emulsions are used to supply or deliver isotonic liquids in small amount i.e. volume to provide large amount of energy to the body. The fat emulsions for intravenous nutrition

generally contain vegetable oil, a phospholipid and emulsifying agent. The examples are: Intralipid, Lipofundins and Lipofunduns

References:-

Remington, The science and practice of pharmacy,21st edition, chapter 20. o Bentley's Textbook of Pharmaceutics,1st edition,chapter 5

Ansel's Pharmaceutical Dosage Forms and Drug Delivery System,loyd

V.Allen,Jr,Howard C.Ansel,10th edition. o Theory and practice of industrial pharmacy, Leon Lachman, Herbert A. Lieberman, Joseph L. Kanig,3rd edition. o www.link.springer.com o www.wiley-vch.de o www.ncbi.nlm.nih.gov o www.particlescience.com o www.researchgate.net o www.pharmacopeia.cn

www.scribed.com

References

Agarwal SP, Rajesh K (2007). Physical Pharmacy. CBS Publisher, Delhi, India, pp. 177-186.

Albers W, Overbeek JTG (1959). Stability of Emulsions of Water in Oil, the Correlation between Electrokinetic Potential and Stability. J. Colloid. Sci., 14: 501-509.

Alfred M, Pilar B, Chun AHC (1993). Physical pharmacy. Lea and febiger, New York, USA, pp.

487-490.

Aulton ME (1996). Pharmaceutics the science of dosage form design. Charchil Livingston, London, United Kingdom, pp. 282-299.

Ashok KG (2005). Introduction to pharmaceutic-1. CBS Publishers, Delhi, India, pp. 116-120.

Carter SJ (2005). Tutorial Pharmacy. CBS Publishers, Delhi, India, pp. 65-66.

Christopher AL, Dawn B (2008). Pharmaceutical compounding and dispensing. RPS, Cambridge, UK, pp. 65-70.

Fie Y, Liu S, Xu J, Lan Q, Wei F, Sun D (2006). Pickering Emulsion Stabilized Solely By Layered Double Hydroxides Particles: The Effect of Salt on Emulsion Formation Stability. J. Colloid. Interface. Sci., 302: 159-169.

Figen T, Ozlem K (2005). A topical w/o/w multiple emulsions prepared with Tetronic 908 as a hydrophilic surfactant: Formulation, characterization and release study. J. Pharma.

Pharmaceut. Sci., 8(2): 299-315.

Gilbert SB, Christopher RT (2002). Modern pharmaceutics. CRC Press, London, UK, pp. 265- 268.

Gilberte MM, Franscoise N (2002). Emulsions in health care applications- An Overview. J. Disp.

Sci. Technol., 23 (1-3): 419-439.

Gonglun C, Daniel T (2005). An Experimental Study of Stability of OilIn-Water Emulsion, Fuel. Proc. Technol., 86: 499-508.

Herbert AL, Martin MR, GILBERT SB (1996). Pharmaceutical Emulsions and Microemulsions, Pharmaceutical Dosage Forms Disperse Systems. Marcel Dekker, INC, New York and Basel, USA, pp. 67-95.

Javed A, Sanjula B, Alka A (2008). Emulsion. Available at : http//JavedAli.Tripod.Com.

John EH (1976). Dispensing of Medication, Mack Publishing Company, Pennysylvania, USA.

pp. 345-358.

Leon L, Herberet AL (2009). The Theory and Practice of Industrial Pharmacy, CBS Publishers, New Delhi, India, pp. 502-531.

Leon S, Alan HM, Paul FS, Larry NS (2004). Comprehensive Pharmacy Review. Lipponcott Williams and Wilkins, Philadelphia, USA, pp. 4751

Donald L. Wise, ‘Handbook of pharmaceutical control release technology’,345-359. Brahmankar D M, Jaiswal sunil, ‘Biopharmaceutics and pharmakokinetics-A treatise’, www.pharmacie-globale.info www.pharmainfo.net www.sysrevpharm.org

please can you tell me , what are the references of the paragraph of 9. PHARMACEUTICAL APPLICATIONS OF EMULSIONS ?

ReplyDeleteCongratulation for the great post. Those who come to read your Information will find lots of helpful and informative tips.h2eau waters.

ReplyDeleteI want to share a testimony, how i was cured from Herpes by DR AGUGU with his herbal remedy. I don't know where to start, I'm 33 years old and i was diagnoses of genital herpes diseases for 5 years. i lost all hope in life but on like any other i still searched for a cure even on the internet and i saw a comment were a lady testify how she was cured by Dr AGUGU i could not believe it at first, i contacted him, He sent me his herbal remedy i used it for 2 weeks and the Herpes virus was cured completely. I went for medical check and the result was negative from Herpes.

ReplyDeleteFor those who have the same problem, or any STD should contact Dr AGUGU via email: agugusolutionhome@gmail.com you can also call or WhatsApp +2349123794867